Ceramic ball valve

- sell:021-32051999

- sell:021-32050777

- fax:021-66099555

Details

- Product Introduction

- Service Promise

- Ordering Process

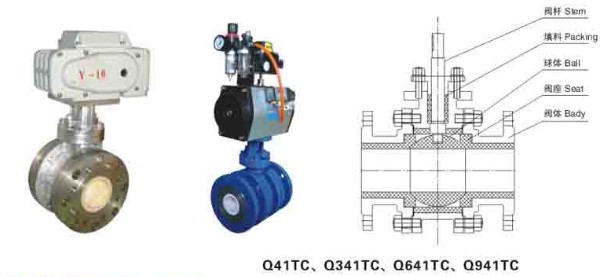

Q41TC Ceramic Ball Valve/Q341TC Worm Gear Ceramic Ball Valve Q641TC Pneumatic Ceramic Ball Valve/Q941TC Electric Ceramic Ball Valve has remarkable characteristics of super corrosion resistance, high temperature resistance, wear resistance and erosion resistance. Widely used in petrochemical, metallurgical, papermaking, power plants, oil refining and other industries, all kinds of acid, alkali, salt gas, liquid, high temperature steam and mud transportation system. It is an ideal substitute for titanium valve and Monel valve under strong corrosion. Zirconia ceramic ball valve has the advantages of low cost, high operation economy and long service life (2-4 times as much as titanium valve). Its driving mode is manual, pneumatic, pneumatic, spring reset, electric and so on. All kinds of special ceramic valves can be designed according to the requirements of users. Suitable for all kinds of acid, alkali, salt liquid, gas medium environment, hard sealing valve is especially suitable for the environment with granular, fibrous medium.

Characteristic

1. All the parts in contact with the medium are structural ceramics, which have high chemical stability and hardness (Rockwell hardness HRC90), second only to diamond. Therefore, the ceramic ball valve has very high wear resistance, corrosion resistance, erosion resistance, and thermal insulation, thermal expansion is small.

2. The sphere is manufactured with advanced grinding equipment and technology. The sphere has high roundness precision and good surface quality. After grinding with the valve seat, the Zr02 ceramics can be used for self-lubrication to obtain good sealing performance.

3. Ceramic good wear resistance, so that the valve durable, high reliability, long service life, is titanium alloy valve and Monel valve 2-4 times.

4. This valve has incomparable absolute advantages for high hardness granular media or soft granular but corrosive media. It is also the only valve suitable for such media at present.

Ceramic ball valve main parts material

valve body | Stem | sphere | valve seat | filler | Applicable medium | Applicable temperature |

WCB | 2Cr13 | Composite ceramics | Composite ceramics | PTFE | Corrosive media such as pulverized coal, coal cinder, powdery particles, etc. | ≤200℃ |

CF8 304 | 0Cr18Ni9 (304) | Composite ceramics | Composite ceramics | PTFE | Corrosive media such as pulverized coal, coal cinder, powdery particles, etc. | ≤200℃ |

CF8M 316 | 0Cr17Ni12Mo2 (316) | Composite ceramics | Composite ceramics | PTFE | Corrosive media such as pulverized coal, coal cinder, powdery particles, etc. | ≤200℃ |

CF3M 316L | 00Cr17Ni14Mo2 (316L) | Composite ceramics | Composite ceramics | PTFE | Corrosive media such as pulverized coal, coal cinder, powdery particles, etc. | ≤200℃ |

design basis | GB | API | ASME |

Design standards | GB/T12237 | API6D | ASME B16.34 |

Structure length | GB/T12221 | API6D | ASME B16.10 |

Connecting flange | GB/T9113 JB/T79 | ASME B16.5、B16.47 | |

Test and inspection | JB/T9092 | API6D | API598 |

Nominal pressurePN | Maximum working pressure at normal temperature | Shell test pressure | Air tightness test pressure | High pressure seal test pressure |

1.6 | 1.6 | 2.4 | 0.6 | 1.76 |

2.5 | 2.5 | 3.8 | 0.6 | 2.75 |

4 | 4 | 6 | 0.6 | 4.4 |

6.4 | 6.4 | 9.6 | 0.6 | 7.1 |

Class150 | 2 | 3 | 0.6 | 2.2 |

Class300 | 5 | 7.5 | 0.6 | 5.5 |

Model | PN | Main dimensions(mm) | |||||||

DN | D | D1 | D2 | b | f | L | n-d | ||

Q41TC Q341TC Q641TC Q941TC | 1.0MPa | 15 | 95 | 65 | 45 | 14 | 2 | 130 | 4×14 |

20 | 105 | 75 | 55 | 16 | 2 | 130 | 4×14 | ||

25 | 115 | 85 | 65 | 16 | 2 | 140 | 4×14 | ||

32 | 135 | 100 | 78 | 18 | 2 | 165 | 4×18 | ||

40 | 145 | 110 | 85 | 18 | 3 | 165 | 4×18 | ||

50 | 160 | 125 | 100 | 20 | 3 | 203 | 4×18 | ||

65 | 180 | 145 | 120 | 20 | 3 | 222 | 4×18 | ||

80 | 195 | 160 | 135 | 22 | 3 | 241 | 4×18 | ||

100 | 215 | 180 | 155 | 22 | 3 | 305 | 8×18 | ||

125 | 245 | 210 | 185 | 24 | 3 | 356 | 8×18 | ||

150 | 280 | 240 | 210 | 24 | 3 | 394 | 8×23 | ||

200 | 335 | 295 | 265 | 26 | 3 | 457 | 8×23 | ||

250 | 390 | 350 | 320 | 28 | 3 | 533 | 12×23 | ||

300 | 440 | 400 | 368 | 28 | 4 | 610 | 12×23 | ||

1.6MPa | 15 | 95 | 65 | 45 | 14 | 2 | 130 | 4×14 | |

20 | 105 | 75 | 55 | 14 | 3 | 130 | 4×14 | ||

25 | 115 | 85 | 65 | 14 | 3 | 140 | 4×14 | ||

32 | 135 | 100 | 78 | 16 | 3 | 165 | 4×18 | ||

40 | 145 | 110 | 85 | 16 | 3 | 165 | 4×18 | ||

50 | 160 | 125 | 100 | 16 | 3 | 203 | 4×18 | ||

65 | 180 | 145 | 120 | 18 | 3 | 222 | 4×18 | ||

80 | 195 | 150 | 135 | 20 | 3 | 241 | 8×18 | ||

100 | 215 | 180 | 155 | 20 | 3 | 305 | 8×18 | ||

125 | 245 | 210 | 185 | 22 | 3 | 356 | 8×18 | ||

150 | 280 | 240 | 210 | 24 | 3 | 394 | 8×22 | ||

200 | 335 | 295 | 265 | 26 | 3 | 457 | 12×22 | ||

250 | 405 | 355 | 320 | 30 | 3 | 533 | 12×25 | ||

300 | 460 | 410 | 375 | 30 | 4 | 610 | 12×25 | ||

2.5MPa | 15 | 95 | 65 | 45 | 16 | 2 | 130 | 4×14 | |

20 | 105 | 75 | 55 | 16 | 2 | 130 | 4×14 | ||

25 | 115 | 85 | 65 | 16 | 2 | 140 | 4×14 | ||

32 | 135 | 100 | 78 | 18 | 2 | 165 | 4×18 | ||

40 | 145 | 110 | 85 | 18 | 3 | 165 | 4×18 | ||

50 | 160 | 125 | 100 | 20 | 3 | 203 | 4×18 | ||

65 | 180 | 145 | 120 | 22 | 3 | 222 | 8×18 | ||

80 | 195 | 160 | 135 | 22 | 3 | 241 | 8×18 | ||

100 | 230 | 190 | 160 | 24 | 3 | 305 | 8×23 | ||

125 | 270 | 220 | 188 | 28 | 3 | 356 | 8×25 | ||

150 | 300 | 250 | 218 | 30 | 3 | 394 | 8×25 | ||

200 | 360 | 310 | 278 | 34 | 3 | 457 | 12×25 | ||

250 | 425 | 370 | 332 | 36 | 3 | 533 | 12×30 | ||

300 | 485 | 430 | 390 | 40 | 4 | 610 | 16×30 | ||

The best quality, first-class service Qigao creates more value for you!

"Qigao Valve" expects to continuously improve service quality and strive for excellence. "Sincere service" is the eternal theme of "Qigao". "Qigao" strictly followsIS09001-2000 Quality system certification requirements, strict quality control, responsibility to people, to ensure the healthy operation of production, sales and service. Strengthen communication with users and provide quality products to our customers with perfection and perfect service. Hereby our factory makes the following commitments:

Product Standards:

Products in strict accordance with ChinaGB、HG Standard and USAPISuch as standard design, manufacturing, acceptance. The hardness of the sealing surface meets the requirements of the state and the width exceeds the national standard.

pre-sale service:

Product introduction, technical exchange, non-standard product design, troubleshooting。

Sale service:

A trustworthy contract guarantees timely delivery and keeps in touch with customers. For special or duplicate products, our factory arranges technicians to use and troubleshoot the products for users.

After sales service:

1、"Qigao" brand product quality period is from the factory12In the month, the implementation of the "three guarantees" service (return, replacement, warranty).

2、During the use of our products, our factory regularly organizes technical and quality inspection personnel to visit and consult users for feedback on product quality, usage status and improvement opinions, so as to further improve product quality.

3、Respond quickly to the quality of user complaints, after-sales service personnel rushed to the scene in 24-36 hours (48 hours outside the province).

4、For after-sales service, users are required to fill out the quality feedback information form after the service and make an appraisal opinion in order to improve the service quality of Qigao.

1、If the customer has special requirements for the product, the following instructions must be provided in the order contract.:

a、Structure length;

b、Connection Type;

c、Nominal diameter, full diameter, reduced diameter, pipe size;

d、Operating medium and temperature, pressure range;

e、Tests, inspection standards and other requirements

2、The factory can configure various types of driving devices according to customer's specific requirements.。

3、If the type and model of the valve are determined by the customer, the customer shall correctly state the meaning and requirements of the model and sign the contract under the condition that the supplier and the buyer understand each other.

4、For futures and order customers, please call us in advance to tell the required valve model, specification, quantity, delivery time and location, and timely transfer to the factory account according to the total 30% deposit or full payment. The rest of the payment is pending. Import before shipment to arrange delivery in time.

Order Process:

1、Customer purchase list fax to021-33872143,Or call us 021-33872141

2、Receive customer purchase list, provide valve model selection and quotation (price list)。

3、Specific agreement: delivery date, special requirements, etc.。

download Google:

1、If the customer has special requirements for the product, the following instructions must be provided in the order contract.:

|

|||||

|

|||||

2、The factory can configure various types of driving devices according to customer's specific requirements.。

|

|||||

3、If the type and model of the valve are determined by the customer, the customer shall correctly state the meaning and requirements of the model and sign the contract under the condition that the supplier and the buyer understand each other.

|

|||||

4、For futures and order customers, please call us first to tell the required valve model, specifications, quantity, delivery time and location, and press the total30%The deposit or full payment will be remitted to our factory account in time., The rest of the payment will be remitted before shipment to arrange delivery in time.。

|

Sale service:

Trustworthy contract, guarantee timely delivery, keep in touch with customers at any time。

For special or duplicate products, our factory arranges technicians to use and troubleshoot the products for users.

After sales service:

1、"Qigao" product quality period is from the factory12Month, practice“Three packs”Service (return, replacement, warranty)。

2、During the use of our products, our factory regularly organizes technical and quality inspection personnel to visit and consult users for feedback on product quality, usage status and improvement opinions.,

In order to further improve product quality。

3、Respond quickly to the quality of user complaints, after-sales service personnel24-36Hours (outside the province48Hour) rushed to the scene。

4、For after-sales service, the user is required to fill out the quality feedback information form after the service and make an appraisal opinion in order to improve the service quality of “Qigao”.。

statement |

|